High power and low energy consumption

1

Tons OF POWER

1

Kw STAND-BY CONSUMPTION

1

MONTHS WARRANTY

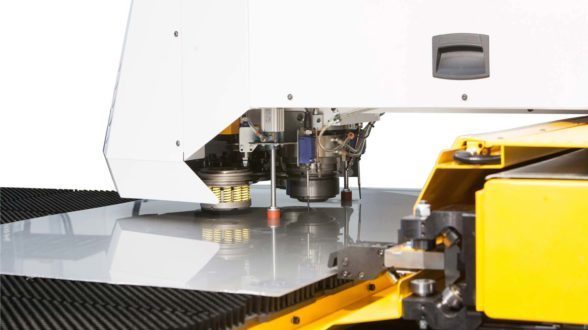

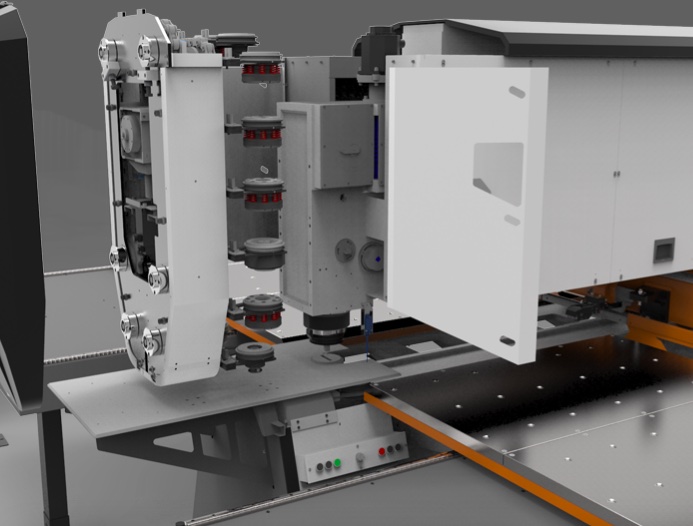

The time has come for a change and go beyond the limits of the old turret punch press concept. TECNOPUNCH technology is the most innovative in the world of punching machines.

Combining simplicity, innovation, performance and productivity at best.

With a simple Internet connection we can safely carry out a comprehensive error diagnosis, drastically reducing machine downtime.

Thanks to its innovative technologies, the new servo drive TP Alpha Matic 5 can be integrated into Industry 4.0 systems.

The TP Alpha Matic 15 turret punching machine features TRUMPF or TECHNOLOGY style tools. You can choose one of the available configurations or customize each single station with standard, special and/or multi-tool tools.

East Gate Project Our Company was founded by a group of specialists with over 22 years of experience in the field of international activities in the supply of various types of industrial equipment, technologies and software.

© 2023 EGP