High power and low energy consumption

1

Tons OF POWER

1

Kw STAND-BY CONSUMPTION

1

MONTHS WARRANTY

We can provide you with suggestions and explanations in English, Turkish, Russian.

With a simple Internet connection we can safely carry out a comprehensive error diagnosis, drastically reducing machine downtime.

Thanks to its innovative technologies, the new servo drive TP Alpha can be integrated into Industry 4.0 systems.

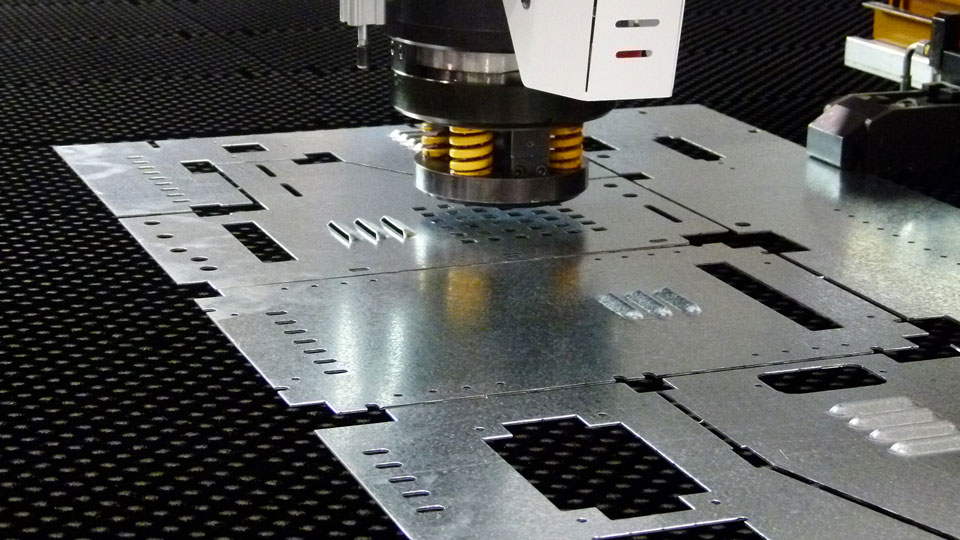

The punching and the movement of the axis are performed manually, using the pedal and the joystick installed on the control panel.

Automatic axis movement (as programmed) and manual punching, using the pedal.

Once the program has been realized with the graphic software TECNOCAM, punching operations and axis movement are automatic.

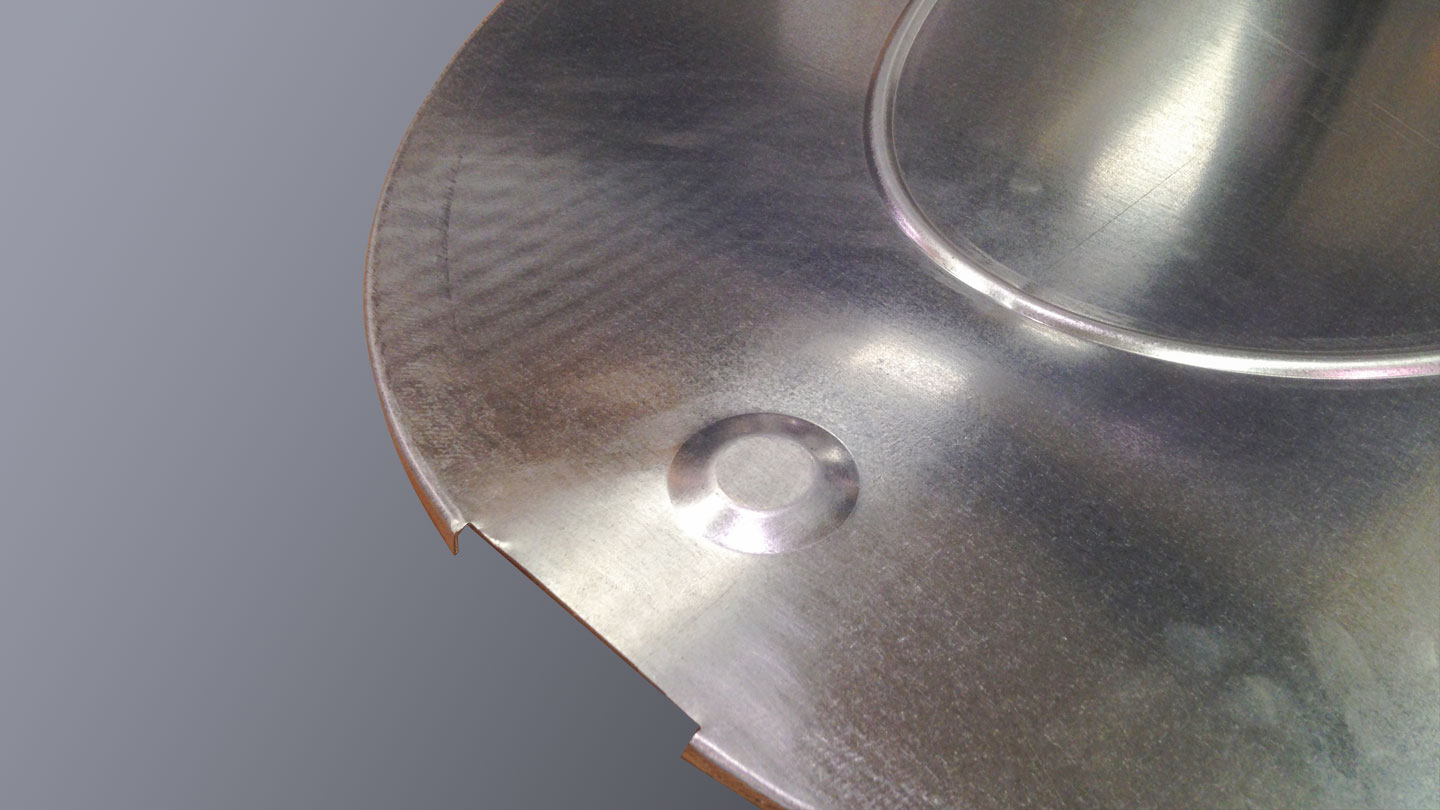

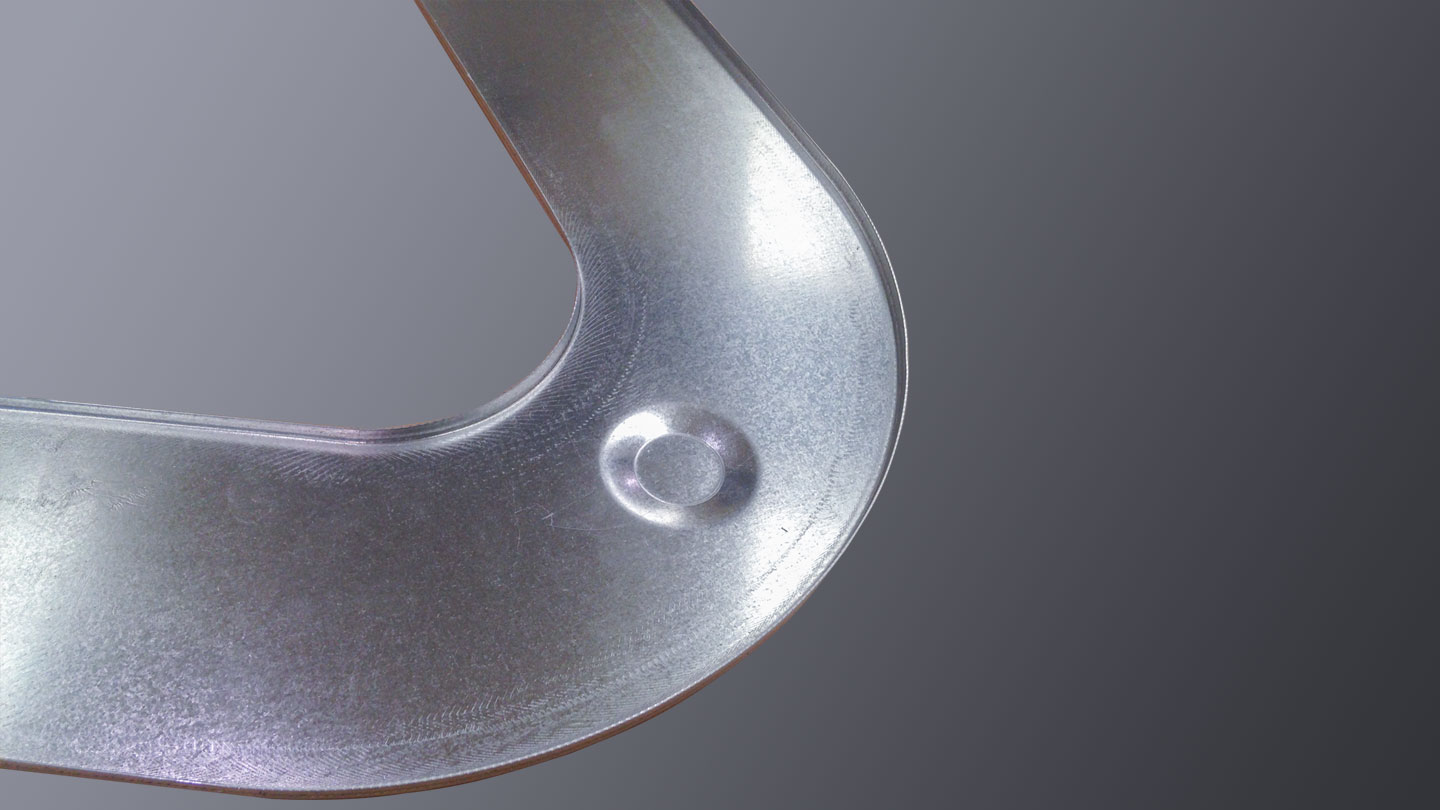

It is equipped with an advanced servo drive punching unit without any hydraulic oil, thus ensuring low energy consumption.

TECNUMERIK is equipped with components provided by the world leader FANUC (CNC, motors, drives and PCs). FANUC guarantees the availability of spare parts for 25 years and offers assistance in 108 countries thanks to its extensive network of subsidiaries.

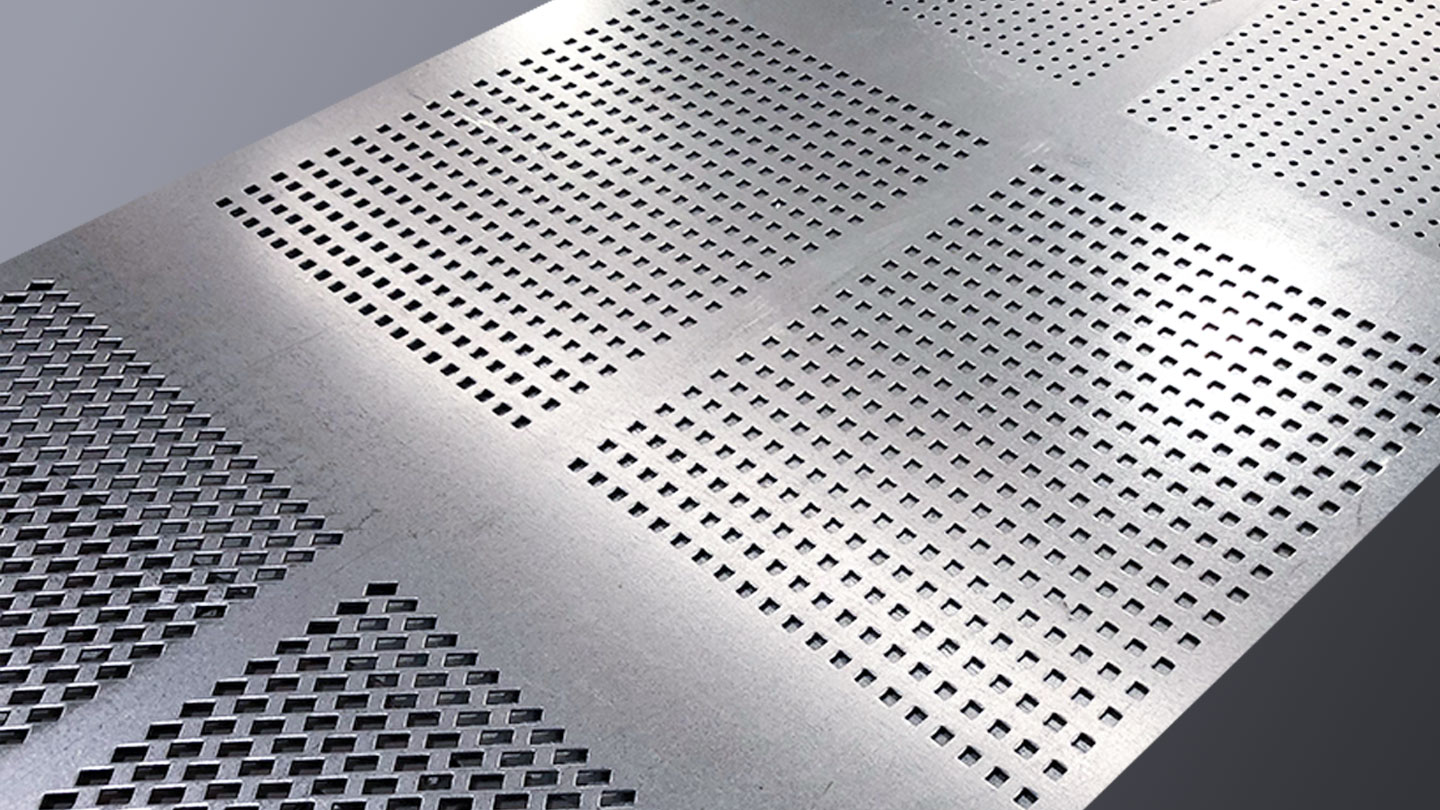

TECHNOLOGY punching machines have always been equipped with the best punching tools. TECNUMERIK can be equipped with TRUMPF style tools but is totally compatible with TECHNOLOGY style tools.

East Gate Project Our Company was founded by a group of specialists with over 22 years of experience in the field of international activities in the supply of various types of industrial equipment, technologies and software.

© 2023 EGP